The Impact of 3D Printing on Manufacturing and Prototyping

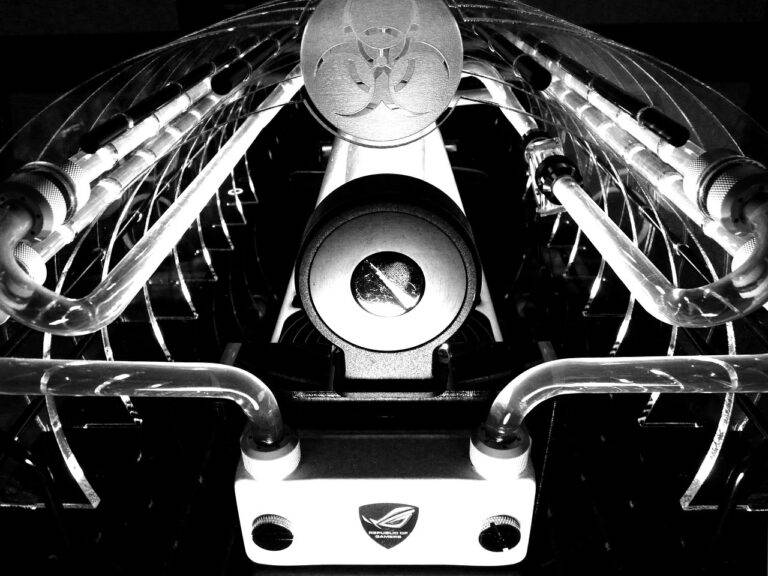

One of the primary advantages of 3D printing in manufacturing is the ability to create complex geometric shapes that would be challenging or impossible to produce using traditional manufacturing methods. This opens up a whole new realm of design possibilities, allowing for the production of innovative and highly customized products.

Additionally, 3D printing in manufacturing can significantly reduce production time and costs. The ability to rapidly prototype and iterate designs in-house can streamline the product development process, leading to faster time-to-market and reduced expenses associated with traditional manufacturing techniques. The cost-effectiveness of 3D printing makes it a valuable tool for small to medium-sized businesses looking to compete in today’s fast-paced market.

Applications of 3D Printing in Prototyping

3D printing has revolutionized the prototyping process for manufacturers across various industries. One key advantage of using 3D printing in prototyping is the ability to quickly create physical models of designs. This allows for rapid iteration and refinement of product designs without the need for expensive and time-consuming traditional manufacturing processes.

In addition to speed, 3D printing offers a high level of customization and complexity that is often not possible with traditional prototyping methods. This technology enables manufacturers to create intricate and detailed prototypes with ease, helping to bring innovative products to market faster and more efficiently.

What are the key advantages of using 3D printing in manufacturing?

Some key advantages of using 3D printing in manufacturing include faster prototyping, cost-effectiveness, design flexibility, and the ability to create complex geometries.

How can 3D printing be used in prototyping?

3D printing can be used in prototyping by creating physical models of products or parts quickly and cost-effectively, allowing for design validation, testing, and iteration before full-scale production.

What are some common applications of 3D printing in prototyping?

Common applications of 3D printing in prototyping include creating architectural models, medical prototypes, automotive parts, consumer products, and industrial machinery components.

Is 3D printing only used for prototyping?

No, 3D printing is not limited to prototyping. It is also used in various industries for small-batch production, customization, tooling, and even end-use parts production.

Can 3D printing replace traditional manufacturing methods entirely?

While 3D printing offers many advantages, it is unlikely to completely replace traditional manufacturing methods. Instead, it is often used in conjunction with other manufacturing processes to optimize production workflows.